Implementation, Consulting, Auditing & Certification at one place . We focus on taking your business to new heights.

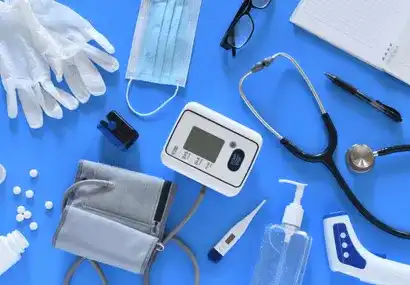

GDP certification, also known as Good Distribution Practices, refers to a quality assurance system for the proper handling, distribution, and transportation of pharmaceutical products and medical devices. These practices ensure that products maintain their integrity, quality, and safety throughout the supply chain, from manufacturers to end-users. The purpose of GDP certification in Kenya is to minimize the risk of product contamination, counterfeiting, and other potential issues that may arise during distribution. It is especially important in the healthcare industry, where the safe and efficient distribution of medicines and medical devices is crucial for patient well-being.

To obtain GDP certification in Kenya, companies involved in the distribution of healthcare products must adhere to specific guidelines and standards. These guidelines cover various aspects of the distribution process, including:

GDP certification in Kenya is usually conducted by accredited third-party organizations through thorough audits of the company’s distribution practices. Successful certification demonstrates the company’s commitment to maintaining high standards in the healthcare supply chain and provides assurance to regulatory authorities, healthcare professionals, and patients that products are handled and distributed safely and efficiently.

It’s important to note that GDP certification requirements in Kenya may vary from country to country, and specific industries might have their own unique certification processes. If you are seeking GDP certification in Kenya for a particular industry or region, it’s best to consult the relevant regulatory authorities or certification bodies to get the most up-to-date and accurate information on the specific requirements applicable to your situation.

The GDP certification process in Kenya (Good Distribution Practices) typically involves several steps to ensure that companies involved in the distribution of pharmaceutical products and medical devices adhere to the necessary quality standards and guidelines. The process may vary depending on the region and the certification body involved, but the following steps are commonly involved:

A GDP certification audit in Kenya is a comprehensive assessment conducted by an accredited certification body to evaluate whether a company complies with the guidelines and standards for the proper distribution, storage, and transportation of pharmaceutical products and medical devices. The primary objective of the audit is to ensure that the company’s distribution practices maintain product quality, safety, and integrity throughout the supply chain.

The GDP certification audit in Kenya typically involves the following key steps:

Before the audit takes place, the company being audited gathers and organizes all relevant documentation related to their distribution processes. This includes standard operating procedures (SOPs), quality manuals, training records, and any other relevant documentation.

The audit begins with an opening meeting between the auditors and the company’s management team. During this meeting, the audit objectives, scope, and schedule are discussed, and any specific concerns or expectations are addressed.

The auditors conduct a thorough examination of the company’s distribution facilities and practices. They assess various aspects, such as storage conditions, temperature controls, transportation processes, documentation, and record-keeping.

The auditors may interview personnel involved in the distribution process to ensure that they understand their roles and responsibilities related to GDP compliance in Kenya.

The auditors compare the company’s distribution practices against the GDP guidelines and standards. They identify any areas of non-compliance or potential risks that could affect product quality or patient safety.

If non-compliance issues are found during the audit, the auditors raise Corrective Action Requests, specifying the areas that need improvement. The company is given an opportunity to address these issues and provide evidence of corrective actions taken.

Once the on-site inspection is complete, the auditors hold a closing meeting with the company’s management to discuss their findings. They may provide initial feedback on any identified issues and explain the next steps in the GDP certification process in Kenya.

After the audit, the certification body prepares a comprehensive audit report detailing the findings, including areas of compliance and non-compliance. The report may include the list of Corrective Action Requests (CARs) if applicable.

Based on the audit findings and the company’s response to the Corrective Action Requests (CARs), the certification body decides whether to grant GDP certification in Kenya. If the company meets all requirements, they are awarded the certification.

Once certified, the company may undergo periodic surveillance audits to ensure ongoing compliance with GDP guidelines in Kenya.

The GDP certification audit in Kenya is a critical process that helps ensure the quality and safety of pharmaceutical products and medical devices throughout the distribution process. Companies that achieve GDP certification demonstrate their commitment to maintaining high standards in the healthcare supply chain.

GDP Certification in Kenya offers numerous advantages to companies involved in the pharmaceutical supply chain. These benefits extend beyond compliance with regulatory requirements, ensuring that pharmaceutical products are distributed with the utmost care and precision. Let’s explore the key benefits that GDP certification brings to the industry:

GDP certification requires companies to implement stringent quality control measures throughout the distribution process. By ensuring proper handling, storage, and transportation of pharmaceutical products, the risk of degradation or contamination is significantly reduced. This, in turn, leads to improved product quality reaching the end-users, ultimately benefiting patients who rely on these medications for their health and well-being.

Counterfeit medicines and tampered products pose serious threats to public health and patient safety. GDP services in Kenya helps combat these risks by implementing security measures that safeguard pharmaceutical products from unauthorized access, tampering, and theft. This enhances the safety and authenticity of the distributed products, building trust among healthcare professionals and patients.

The pharmaceutical industry is heavily regulated, and non-compliance with the established guidelines can lead to severe consequences. GDP certification ensures that companies meet the necessary regulatory requirements set forth by agencies like the FDA, EMA, and WHO. By maintaining compliance, companies can avoid penalties, legal issues, and potential disruptions to their operations.

GDP certification in Kenya involves a comprehensive assessment of potential risks in the distribution process. Identifying and addressing these risks helps companies proactively mitigate potential threats to the supply chain. From handling sensitive medications to maintaining proper temperature controls during transportation, GDP practices significantly reduce the likelihood of product damage and loss.

In the pharmaceutical industry, trust and reliability are crucial factors when establishing partnerships with other companies. GDP certification Services in Kenya as an assurance of a company’s commitment to quality and compliance. When seeking distribution partners or collaborating with manufacturers, GDP-certified companies are preferred due to their demonstrated adherence to industry best practices.

For patients and healthcare providers, knowing that pharmaceutical products come from GDP-certified sources provides an additional layer of confidence. GDP certification in Kenya assures consumers that the products they receive are authentic, safe, and handled with utmost care, bolstering their trust in the medicines they prescribe or consume.

Obtaining GDP certification in Kenya sets a company apart from its competitors. It becomes a testament to the company’s dedication to quality and safety in the pharmaceutical supply chain. In an industry where reputation matters, being GDP-certified can attract more clients and customers, ultimately leading to increased market share and growth opportunities.

GDP certification is not a one-time achievement; rather, it promotes a culture of continuous improvement. Companies must regularly review and update their distribution practices to maintain compliance with evolving regulations and industry standards. This commitment to improvement ensures that the supply chain remains efficient, secure, and aligned with the latest best practices.

Obtaining GDP (Good Distribution Practices) Certification is an essential step for pharmaceutical companies committed to maintaining the highest standards in their distribution practices. While the certification process involves costs, it is important to view it as an investment in ensuring product quality, safety, and regulatory compliance. The actual GDP certification cost in Kenya can vary depending on several factors. Let’s explore the key components that contribute to the cost of GDP certification:

Pharmaceutical manufacturers are a key player in the supply chain, responsible for producing a wide range of medications and medical devices. These companies are eligible for GDP Certification as they play a critical role in ensuring that products are appropriately packaged and labeled for safe distribution.

Wholesale distributors serve as intermediaries between manufacturers and various healthcare facilities, pharmacies, and other points of sale. These companies are eligible for GDP Certification because they are responsible for handling, storing, and transporting pharmaceutical products to different locations while maintaining the products’ integrity and quality.

Many pharmaceutical companies outsource their logistics operations to third-party logistics providers (3PLs) to handle the complexities of distribution. 3PLs are eligible for GDP Certification as they directly handle the physical movement of pharmaceutical products, making adherence to GDP guidelines crucial for product safety.

Pharmacies and retail outlets that dispense prescription and over-the-counter medications to consumers are eligible for GDP Certification. These entities are the final link in the distribution chain, and their compliance with GDP guidelines ensures that patients receive genuine and safe products.

Medical devices are another critical component of the healthcare industry. Companies involved in the distribution of medical devices are eligible for GDP Certification to guarantee the safe and efficient delivery of these products to medical facilities and end-users.

Hospitals and healthcare facilities that store and administer pharmaceutical products to patients must also adhere to GDP guidelines. Ensuring proper storage conditions and handling practices are crucial to maintaining the quality and efficacy of medications.

Companies involved in conducting clinical trials and research studies play a significant role in drug development and testing. These entities are eligible for GDP Certification to maintain the integrity of investigational products throughout the trial process.

Companies engaged in international trade of pharmaceutical products, either as exporters or importers, must comply with GDP guidelines to ensure that products remain safe and effective during transportation across borders.

CMOs that manufacture pharmaceutical products on behalf of other companies are eligible for GDP Certification, as they handle critical stages of the supply chain and must adhere to the same standards as manufacturers.

Government agencies and regulatory bodies overseeing the pharmaceutical industry may also seek GDP Certification to set an example and demonstrate their commitment to enforcing and upholding high-quality distribution practices.

GDP Consultants in Kenya play a crucial role in the pharmaceutical industry, offering specialized expertise and guidance to companies seeking to enhance their distribution practices. These consultants are experienced professionals well-versed in GDP guidelines and regulatory requirements. The pharmaceutical supply chain is a complex and highly regulated network, and adhering to GDP guidelines is essential to guaranteeing product quality and safety. GDP Consultancy in Kenya bridges the knowledge gap and help companies navigate the intricacies of distribution practices. Their services are invaluable for achieving and maintaining GDP Certification in Kenya, which is a testament to a company’s commitment to meeting the highest industry standards.

Engaging GDP Consultants in Kenya offers numerous benefits to pharmaceutical companies, including:

GDP Consultants in Kenya bring specialized knowledge and expertise in GDP guidelines and regulatory requirements, providing companies with a reliable source of information and guidance.

By helping companies identify and address potential risks in the distribution process, GDP Consulting services in Kenya contribute to mitigating supply chain vulnerabilities and minimizing the likelihood of product damage or loss.

GDP certification Consultants in Kenya streamline processes and ensure efficient distribution practices, leading to potential cost savings and increased operational efficiency.

GDP Certification in Kenya obtained with the assistance of Consultants enhances a company’s reputation and instills confidence in stakeholders, including customers, partners, and regulatory bodies.

GDP Consultants stay up-to-date with the latest industry trends and best practices, ensuring that their clients implement the most effective and compliant distribution strategies.

Any company involved in the distribution of pharmaceutical products, including manufacturers, wholesalers, distributors, and pharmacies, may require GDP Certification. Additionally, companies engaged in the international trade of pharmaceuticals may seek GDP Certification to comply with various regional and international regulations.

During a GDP audit in Kenya, several key elements are assessed to determine compliance. These include proper handling and storage practices, temperature control, transportation procedures, record-keeping, and product security measures.

The time required to obtain GDP Certification in Kenya can vary depending on the company’s current level of compliance and the complexity of its distribution process. Generally, the preparation process, including internal audits and corrective actions, may take several months. Once the company is ready, the actual certification process can take a few weeks to complete.

A GDP Certification Audit in Kenya aims to assess and ensure that pharmaceutical products are distributed safely, efficiently, and in compliance with regulatory guidelines. This process guarantees product quality and minimizes risks associated with distribution, safeguarding the supply chain.

The frequency of GDP audits varies based on factors like the type of product, the risk involved, and regulatory requirements. Generally, audits are conducted at least once every two years, but high-risk products may require more frequent audits.

GDP Consultants in Kenya are specialized professionals who provide guidance and support to pharmaceutical companies in adhering to Good Distribution Practices (GDP). Their primary role is to ensure that companies comply with regulatory requirements, maintain product quality, and implement efficient distribution processes throughout the pharmaceutical supply chain.

Yes, GDP Consultants are well-versed in international GDP regulations and standards. They assist companies engaged in international trade to navigate the complex requirements of different countries and regions. Ensuring compliance with international GDP regulations is crucial for smooth cross-border distribution.

B2BCERT is a Solutions & Service organization, specialized in management consulting, Trainings, Assessments, Certification & Managed Services

MOST SEARCHED ON B2BCERT: ISO 9001 Certification | CE Certification | ISO 22000 Certification | NEMA Certification | ISO 27701 Certification | ISO 27032 Certification | ISO 22483 Certification | REACH Certification | ISO 22301 Certification | ISO 42001 Certification | ISO 41001 Certification | ISO 21001 Certification | ISO 15189 Certification | GMP Certification | GDPR Certification | GDP Certification | GLP Certification | HIPAA Certification | PCI DSS Certification | SOC 1 Certification | KOSHER Certification | NEMA Certification | Certificate of Conformity | GACP Certification | FSSC 22000 Certification | OHSAS 18001 Certification | HACCP Certification | SA 8000 Certification | SOC 2 Certification | VAPT Certification | ROHS Certification | BIFMA Certification | FCC Certification | HALAL Certification

ISO CERTIFICATIONS: ISO 9001 Certification | ISO 14001 Certification | ISO 45001 Certification | ISO 22000 Certification | ISO 27001 Certification | ISO 13485 Certification | ISO 17025 Certification | ISO 27701 Certification | ISO 20000-1 Certification | ISO 27032 Certification | ISO 22483 Certification | ISO 26000 Certification | ISO 22301 Certification | ISO 42001 Certification | ISO 27017 Certification | ISO 27018 Certification | ISO 50001 Certification | ISO 27014 Certification | ISO 29990 Certification | ISO 37001 Certification | ISO 41001 Certification | ISO 21001 Certification | ISO 55001 Certification | ISO 28000 Certification | ISO 22716 Certification | ISO 15189 Certification | ISO 41001 Certification

PRODUCT CERTIFICATIONS: FSSC 22000 Certification | OHSAS 18001 Certification | HACCP Certification | SA 8000 Certification | GMP Certification | GDPR Certification | GDP Certification | GLP Certification | HIPAA Certification | PCI DSS Certification | SOC 1 Certification | SOC 2 Certification | VAPT Certification | CE Certification | ROHS Certification | BIFMA Certification | FCC Certification | HALAL Certification | KOSHER Certification | NEMA Certification | REACH Certification | Certificate of Conformity | GHP Certification | Free Sale Certification | FDA Certification | GACP Certification

WHAT IS B2BCERT: B2BCERT is one of the leading service providers for International recognized standards and Management solutions for Business development, process Improvement, Consulting & Certification services for various International Standards like ISO 9001, ISO 14001, ISO 45001, ISO 22000, ISO 27001, ISO 20000, CE Marking, HACCP & many more. B2BCERT works on the values of trust, fairness & genuine respect for our customers, employees, and business partners.B2BCERT provides internationally recognized standards and management solutions, specializing in ISO and related certification services. Headquartered in Bangalore, India, we have a global presence in the Middle East and Africa. Our team of 30+ professionals ensures tailored solutions by partnering with leading certification firms.

B2BCERT Serves In: India | Nepal | Singapore | Afghanistan | Philippines | Malaysia | Jordan | Turkey | Sri Lanka | Saudi Arabia | Oman | UAE | Kuwait | Yemen | Qatar | Lebanon | Iran | Iraq | Bahrain | South Africa | Egypt | Nigeria | Kenya | Ghana | Tanzania | Zimbabwe | Cameroon | Uganda | USA | UK | Germany | Australia | New Zealand | Canada | Italy | Botswana | Brunei | Cambodia |

Service providing Sectors: Information Security | Manufacturing | Software Companies | Pharmaceuticals | Architecture | Construction | Food & Beverages | News & media | Science & Biotechnology | Electronics Industry | Telecommunications | Hospitals | Import & Export Businesses | Schools & Colleges | Textile Industries | Banks | Aerospace Manufacturing | Hotels & Restaurants | Organic Products | Mining & Renewable Business | Real Estate Business | Public Administration | Wholesale Trade | Supply Chain Management | Agrochemicals | Government Services | Electricity | Regulatory Agencies | Fitness and Wellness | Property Management | Rental Services | Warehousing | Delivery Services | Stores and Shops | IT Support | Event Planning | Consulting | Financial Advisory |

WHY B2BCERT: 1. Expertise Across Standards: B2BCERT is a leader in providing comprehensive solutions for a wide range of international standards, including ISO 9001, ISO 14001, ISO 45001, ISO 22000, ISO 27001, ISO 20000, CE Marking, and HACCP. Our deep knowledge ensures that your business meets and exceeds industry benchmarks with confidence. 2. Tailored Solutions: We understand that every organization is unique. B2BCERT offers customized consulting and certification services designed to fit your specific needs and objectives. Our team works closely with you to develop strategies that enhance your business processes and meet regulatory requirements.3. Global Presence: With headquarters in Bangalore, India, and a strong foothold in the Middle East and Africa, B2BCERT combines local expertise with a global perspective. Our international reach allows us to provide consistent, high-quality service wherever you operate.4. Trusted Partners: We collaborate with leading certification firms to offer you the best possible service. Our established relationships with top certification bodies ensure that you receive credible and widely recognized certifications that enhance your business’s reputation.5. Commitment to Values: At B2BCERT, our core values of trust, fairness, and respect drive everything we do. We are dedicated to building lasting relationships based on integrity and genuine respect for our clients, employees, and partners.6. Professional Team: Our team of over 30 skilled professionals brings a wealth of experience and dedication to every project. We are committed to delivering excellence and supporting you through every step of your certification journey.7. Comprehensive Support: From initial consultation to certification and beyond, B2BCERT provides end-to-end support. We are here to guide you through the complexities of compliance and help you achieve your business goals efficiently and effectively.